Do you want to BE a Roman Gladiator? Legionary? Centurion? General?

Senator? We've been living your dream for years!

Be the Hero!

Live the Dream.

SITE

INDEX

This site is best viewed at 1024x768

Look

for us on

Malice

the Webseries, a Phil Cook Eagle Films Production

|

|||

|

|||

| BUILDING YOUR SHIELD | |||

|

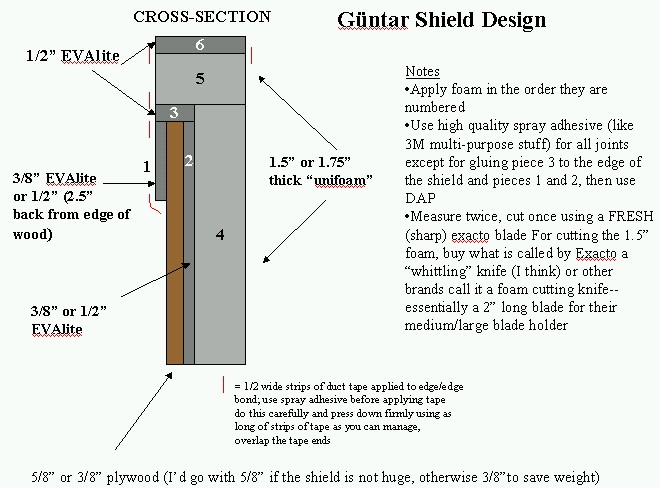

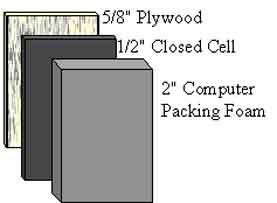

Cut a piece of plywood into the desired shape, rounding all corners to eliminate the danger of sharp edges. The first thing you should do after you measure and mark where you want to put the strap/handle. Glue closed cell on the shield backing, as seen in the far right graphic. This will act as a buffer between the board and your arm to absorb impacts and reduce the chance of injury to yourself. Do this BEFORE you drill and strap the shield. Use washers! MEASURE TWICE, drill once and strap once.

|

|

|

|

|

Cut your straps to the necessary lengths and bolt them to your shield. Make certain the bolt excess faces your side of the shield. For the hand, I recommend a durable door handle that fits your hand comfortably. Next, glue closed cell foam around back edges, front, and then the edges of your shield as in the diagram. Putting foam on the front and back first will provide a larger surface area for your edges, giving you more surface area to adhere to. Following this, glue open cell "computer packing foam" to the front of your shield, making sure the piece you apply is cut to the precise dimensions of your shield face. Apply computer packing foam to your edges, and finally apply strips of closed cell to the outside edges to ensure progressive resistance. Reinforce your shield padding's structural integrity by applying strips of duct tape to every glued seam.

Once you have done this, get some durable red cloth (canvas is best) and secure it snugly over the entire surface and edges of the shield, stapling it on the inside, or your side. Paint Rome's shield logo on the front in gold or yellow.

|

|||